TST IoT Platform reshapes the new paradigm of steel wire rope safety monitoring

2026-01-23

Currently, China is vigorously promoting the digital transformation of its industries, and factories and enterprises are accelerating their transformation. Luoyang TST Flaw Detection Technology Co., Ltd., as a pioneer in the field of special equipment safety monitoring, actively responds to the strategy of China and has dedicated itself to creating the "TST Safety & Smart Digital IoT Supervision Service Platform."

This platform deeply integrates cutting-edge IoT, big data, and intelligent sensing technologies with traditional industrial safety needs, aiming to build an intelligent, and decision-making digital protection network for the safe operation of steel wire ropes (including steel core belts), the "lifeline" in critical processes such as lifting, hoisting, and transportation.

In recent years, Luoyang TST Flaw Detection Technology Co., Ltd. has actively participated in the accelerated advancement of digital technology and industrial digitalization, deeply implementing the country's new development philosophy and firmly adhering to the development goals of becoming a strong manufacturing enterprise and a strong network enterprise.

With its outstanding R&D capabilities and innovative spirit, TST has successfully explored and developed a series of new digital products and platforms, injecting vitality into the construction of smart cities and smart construction sites.

As a core load-bearing component of various lifting and transportation equipment, the health of wire ropes directly impacts production safety, operational efficiency, and cost control. Traditional inspection methods, often relying on periodic offline sampling, suffer from inherent limitations such as large monitoring blind spots, delayed early warnings, dependence on personnel experience, and inability to assess damage trends in real time. These limitations make it difficult to completely prevent major safety accidents and production interruptions caused by sudden rope breakage.

The TST platform precisely addresses this industry pain point, redefining the dimensions of wire rope safety monitoring: shifting from "periodic sampling" to "all-time, panoramic online monitoring," from "post-incident investigation" to "pre-incident early warning and trend prediction," and from "isolated data" to "full lifecycle health management." The platform focuses on providing customers with comprehensive lifecycle assessment and analysis services for wire ropes from commissioning to scrapping, elevating safety supervision to a new level of digitalization and intelligence.

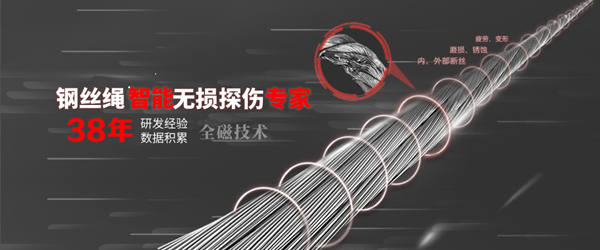

The platform's superior performance is rooted in TST's unique, internationally leading intelligent sensor technology. These high-precision, high-reliability sensors are meticulously deployed at key monitoring points of the wire rope, enabling millisecond-level, 24/7 continuous real-time data collection of internal and external damage (such as broken wires, wear, corrosion, and deformation) and load changes in the wire rope without affecting normal equipment operation.

The application of the TST Safety & Smart Digital IoT Monitoring Service Platform brings significant multi-dimensional value to industrial enterprises:

Safety Enhancement: Transforming passive defense into proactive early warning fundamentally and significantly reducing the risk of serious safety accidents caused by sudden wire rope breakage, ensuring the safety of personnel and assets.

Production Continuity Assurance: Predictive maintenance effectively avoids unplanned downtime, ensuring the continuity and stability of production processes and directly improving capacity utilization.

Operating Cost Optimization: Precise life assessment avoids premature replacement or overuse of wire ropes, and scientific maintenance strategies reduce manpower inspection costs and unexpected repair expenses, achieving cost reduction and efficiency improvement.

Leap in management efficiency: Digital management makes safety responsibilities clearer, processes more standardized, and decision-making more efficient, thereby improving the company's overall level of modern governance and core competitiveness.

prev: TST concluded 2025 with an outstanding performance as a gift for 2026!

next: Back to List