- HOME

- NEWS

- CASES

- INDUSTRIES

-

PRODUCTS

-

TST Portable Wire Rope Tester

-

TST Portable Elevator Wire Rope Tester

-

TST Online Elevator Wire Rope Tester

-

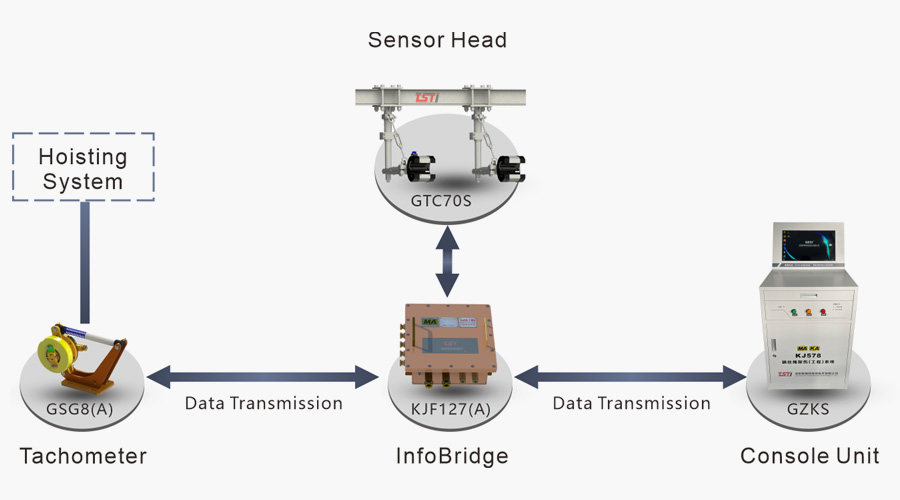

TST Wire Rope Online Automatic Inspection System

-

TST Online Wire Rope Monitoring System With AI visual recognition

-

Steel Core Conveyor Belt Intelligent Monitoring System

-

TST Steel Core Conveyor Belt Intelligent Monitoring System With AI visual recognition

-

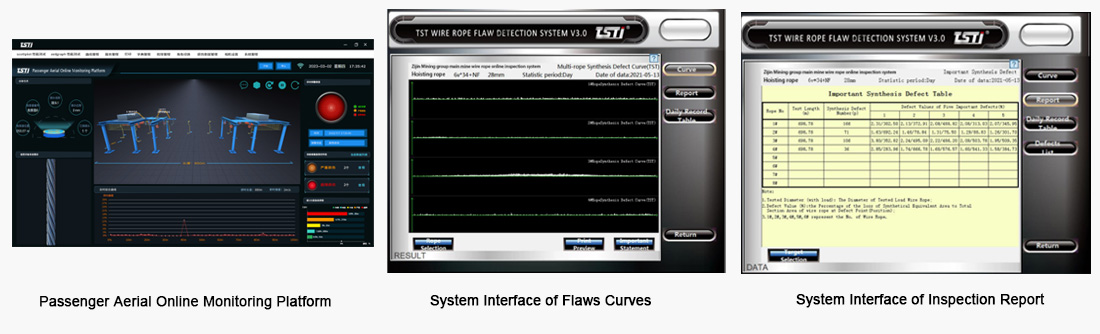

Passenger Aerial Online Ropeway Intelligent Monitoring System

-

TST Passenger Aerial Online Ropeway Intelligent Monitoring System With AI visual recognition

-

- SERVICE

- ABOUT US

- CONTACT