Port-specific TS-X11 Series Steel Wire Rope Flaw Detection (Portable) System

Inspection Site of Yingkou Port

Inspection Site of Qingdao Port

Inspection Site of Yantai Port

02

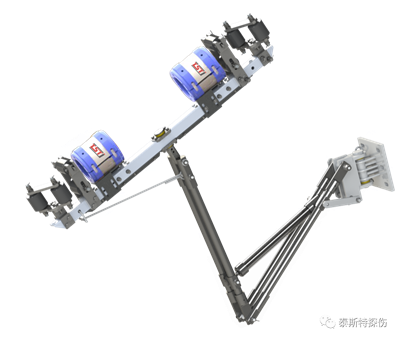

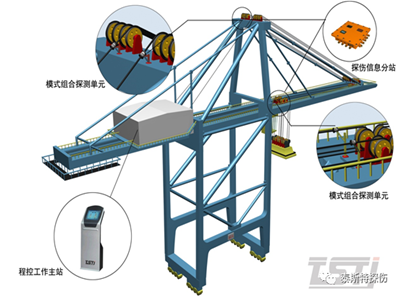

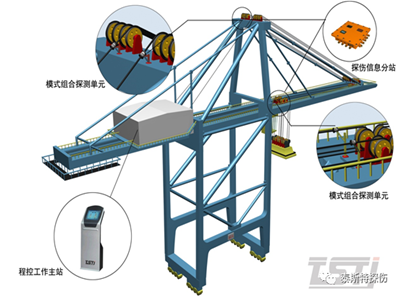

Port-used TST Wire Rope Flaw Detection (Online) system V3.0

Apply to: Port equipment with wire rope such as ship unloaders, gantry cranes, winches, tractors and portal cranes

03

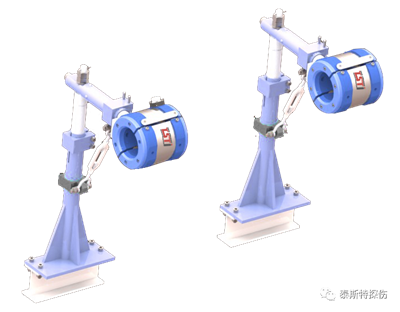

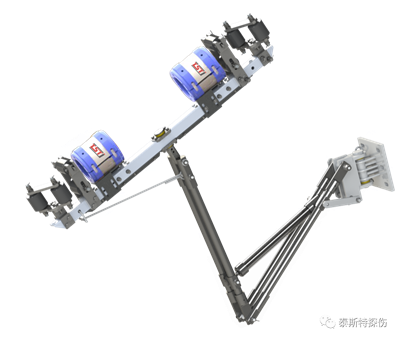

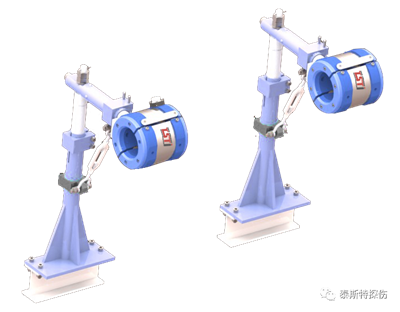

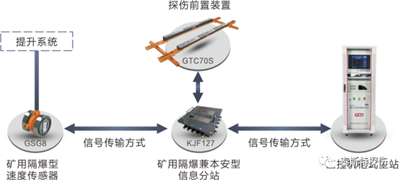

Port Dedicated Endless Rope Online Real-Time Monitoring System

It can adapt to the working conditions of the non-removable cable gripper

04

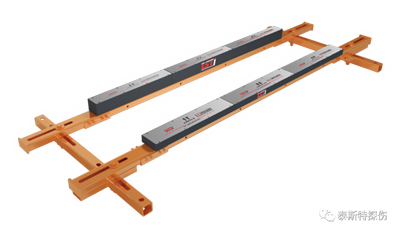

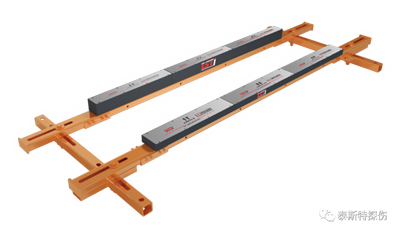

TST Conveyor Belt Steel Core Flaw Detection System

1 Schematic Diagram of product Application Site

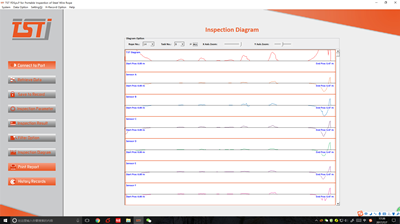

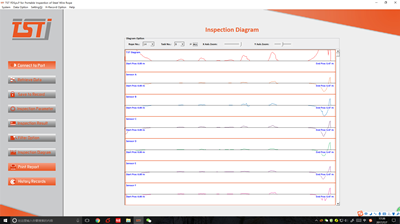

Inspection Report

Advantages

01 Quantitative Inspection

Precise and quantitative positioning detection

02 Qualitative Inspection

According to the pattern recognition software, the flaw types of wire rope such as internal and external fatigue, corrosion, broken wire, abrasion,pitting can be judged;

03 Wide-Range Inspection

The effective extraction distance of the signal (with the surface of the tested wire rope) can be up to 30mm;

04 High-Speed Inspection

Electromagnetic response supports detection speed of 30m/s;

05 Intelligent Inspection

AI intelligent algorithm, intelligent automatic quantitative discrimination, classification and statistics of various internal and external damages, and accurate assessment of the safety status of wire ropes;

06 Accurate Inspection

Unique structure design and anti-interference circuit design

Electromagnetic induction signal-to-noise ratio: S/N>85dB;

Adopt electromagnetic compensation technology and introduce variable tracking correction technology

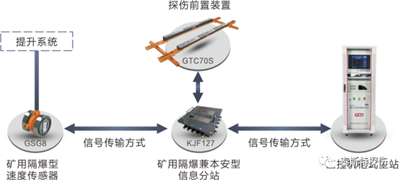

07 LOT cloud technology

Integrate data interconnection analysis technologies such as the Internet of Things(LOT), big data, cloud computing, etc., so that safety monitoring information can be expanded from local to regional scale, and distributed terminal information into the overall safety information database to achieve "borderless" interconnection of safety management.